History of Vebko

In 1994, Dr. Hossein Askarian Abyaneh (chairman of the Board of Directors and Professor at Amir Kabir University of Technology), decided to build a relay test device in consultantions with different professors abroad.

Dr. Farzad Razavi (CEO of Vebko, a graduate, former PhD candidate of Dr. Askarian , also worked with him while being an undergraduate student, is also one of the founders of Vebko Company.

This lead to a device called RENAISSANCE with common dimensions, which had a very weak hardware and software accuracy and capabilities. In 2009, a one-year-contract was signed with the Semnan Regional Electrical Company (SREC). CPRT100 was manufactured with the same dimensions as the previous version with acceptable hardware accuracy, but very limited functionalities and many software problems. In 2004, TREC, Zanjan Regional Electrical Company (ZREC) and Esfahan Regional Electrical Company (EREC), each signed a contract and purchased a device in order to support Vebko.

Mr. Farooghi and Mr. Kabirnia were responsible for the hardware and software, respectively. Mr. Barzegar and Mr. Sedaghat were responsible for the hardware and software of the device, respectively.

After releasing this version of the device, the team concluded that manufacturing a device at this level of technology would not work. The group under the supervision of Mr. Barzegar also announced that they would sell the device independently in Iran. They sold several devices in Iran in which AUT, Dr. Askarian, and Dr. Razavi did not play any role. In 2010, the group concluded that it is possible to receive funding from various sources to re-design and manufacture the device. Finally, in 2013, a contract was signed with the Vice Presidency of Science and Technology for manufacturing a national relay tester and relay. The decision was to found a knowledge-intensive company to conduct all activities, including research, design, and manufacturing the device are within that company.

First, Vebko decision was to manufacture several products, but after a short time, it turned out if the company focuses on two products, the quality of product would improve. This process started in 2013 and the first product called AMT105 was produced in October 2015 used and tested in Tehran Power Transmission Maintenance Engineering Company (METANIR) and Bakhtar Regional Electric Company (BREC) for the first six months.

Initially, Tehran Regional Electrical Company (TREC) sponsored the project. The task was designed to provide hardware and software for those off-campus in contact with students. Dr. Askarian and Dr. Razavi acted as top supervisors; research and scientific materials were prepared with the help of Amir Kabir’s students who in turn took responsibilities of its production. The first device called CPRT was made in the same year, where Mr. Amiri and Mr. Karimi took the responsibility for hardware and software, respectively. The project took two years and resulted in a very large hardware, 0.5m×1m×2m, with a very low accuracy and weak software.

After the mentioned version, in 2000, TREC signed a year and half contract with Amir Kabir University of Technology (AUT), working with the same technical team which lead to the production of CPRTP with two small items of luggage. Once again the precision of hardware was still low and weak; TREC purchased two CPRTPs.

Two important decisions were made in 2016, when Vebko started selling to more clients: First decision was to create Telegram group so that everyone can give feedback. Vebko has used these comments to improve the device, which led to adding more options. In January 2016, it was decided that any hardware problems must be reported on the website and Telegram group in a way that all users become aware of the problems and its solution. These two decisions helped Vebko to optimize the hardware and add software options. In October of 2015, the authorities in the Ministry of Petroleum were encouraged by contractors to use the device. In the beginning, because the tester has a high technology and there were certain concerns in this regard, the authorities in the Ministry of Petroleum were reluctant to use this device, but at the end of 2015, AMT105 showed a good performance compared with foreign devices. The authorities finally approved it in different phases of Asaluyeh, and the company was able to enter the Vendor List of Ministry of Petroleum in November 2015. In January of 2015, a decision was made so that AMT105 can be used for various applications, in addition to testing relays, such as key testing, CT test, transformer testing, and so forth. Then, the related functions have been added to the device.

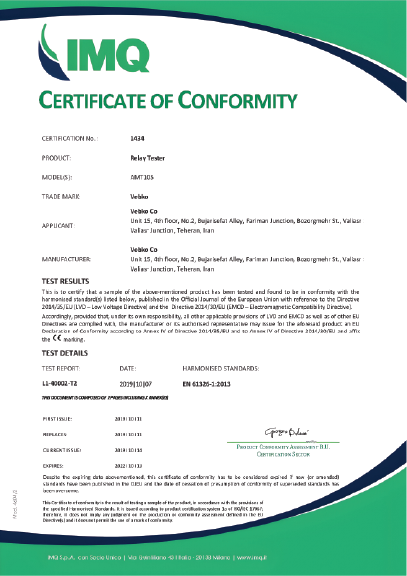

To date, around 875 Tester devices,around 120 relay devices have been sold and used by electrical engineers all over the country. The first industrial product of this company entered the market in 2014 and within three years more than 300 relay tester devices were sold to important industrial centers of electricity, oil and gas as well as some universities. Vebko is a science-based company, stablished in 2014 by order of the Science and Technology Vice-Presidency of Iran to manufacture national relay tester device under the supervision of Amirkabir University of Technology. AMT105 is a universal solution to testing all types of relays and protective equipment, circuit breakers, thermal cables and sensors as well as power, current, voltage and capacitor-voltage transformers. Because of these features, this device is capable of testing different kinds of relays and protective equipment: Six 32A current sources (64A in three-phase mode, 128A in single-phase mode), four 150 V voltage sources (450 Vin single-phase mode), current and voltage combination cable, 8 analog binary inputs, 2 DC analog current and voltage inputs with high accuracy, 4 binary outputs, DC voltage source (212 V).

Overview

Relay Tester AMT105 - AMT205

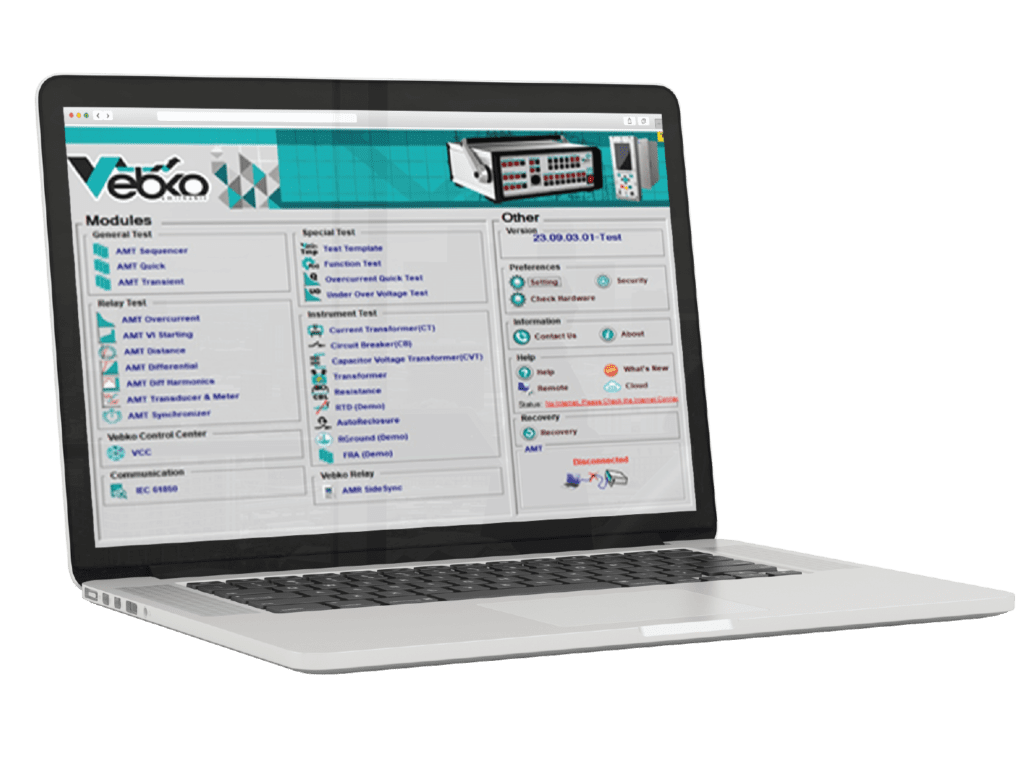

- Capabilities related to testing protective relays and measurement equipment.

- Ability to test various types of meters and transducers.

- Ability to perform power transformer tests.

- Ability to perform current transformer (CT) tests.

- Ability to perform switching and sequencer tests.

- Ability to perform cable resistance tests.

- Ability to perform RTD (Resistance Temperature Detector) tests.

Capabilities related to testing protective relays and measurement equipment include:

- Testing various types of electromechanical, static, and numerical relays.

- Support for all Xrio and Rio file formats.

- Conducting transient tests.

- Performing Point to Point or End to End tests.

- Equipped with built-in GPS and Wi-Fi modules.

- Automatic execution of tests.

- Comprehensive test reports.

- Automatic filling of report forms for different companies.

- Compatibility with Windows operating systems (XP, 7, 8, 10, 11).

- Support for Android and iOS operating systems.

- Automatic saving Redo and Undo actions.

- Persian user guide in PDF format.

- Utilization of Bootloader technology for firmware updates.

- Instructional videos.

Capable of Testing Circuit Breakers(CB) and Sectioners

- Timing Test

- Contact Resistance

- Minimum Voltage to Operate Circuit Breaker

Capable of Testing Voltage Transformers and Capacitor Voltage Transformers(VT/CVT)

- Secondary Burden

- Short-Circuit Impedance

- Resistance

- Excitation

- Ratio

Capable of Testing Current Transformers(CT)

- Excitation (Saturation)

- Hysteresis curve

- Ratio using current or voltage

- Polarity using current or voltage

- Phase error

- Winding resistance

- Secondary burden

Capable of Testing Power Transformers

- Winding resistance

- Ratio (TTR)

- No-Load Current

- Vector group

- Magnetic balance

- Tap changer continuity

- Demagnetizing

Capable of Testing transducers and meters

- Highly precise in testing transducers and meters

- Equipped with a pulse counter to automatically read energy

Capable of Testing RTD

Features

software Features

- Powerful software environment with user-friendly interface for configuring various functions

- Hardware Configuration software module for configuring relay hardware

- VFC Configuration software module for logic programming, function selection, and block-based assignment

- Assigning inputs and outputs of each function to digital relay outputs, LEDs, etc. using Drag and Drop

- Signal Routing software module for assigning digital inputs, outputs, and LED relay outputs

- Online Measurement software module for real-time monitoring of voltage and current signal values

- Record Data software module for accessing relay processing level information such as events, errors, and disturbances

- Ability to export disturbances in Comtrade format

- Ability to apply Comtrade files stored by relays or simulated to relay algorithms and evaluate function performance

- Four adjustable groups

- Ability to export relay settings in XRio format

- Possibility to update the firmware of the desired relays

Representatives